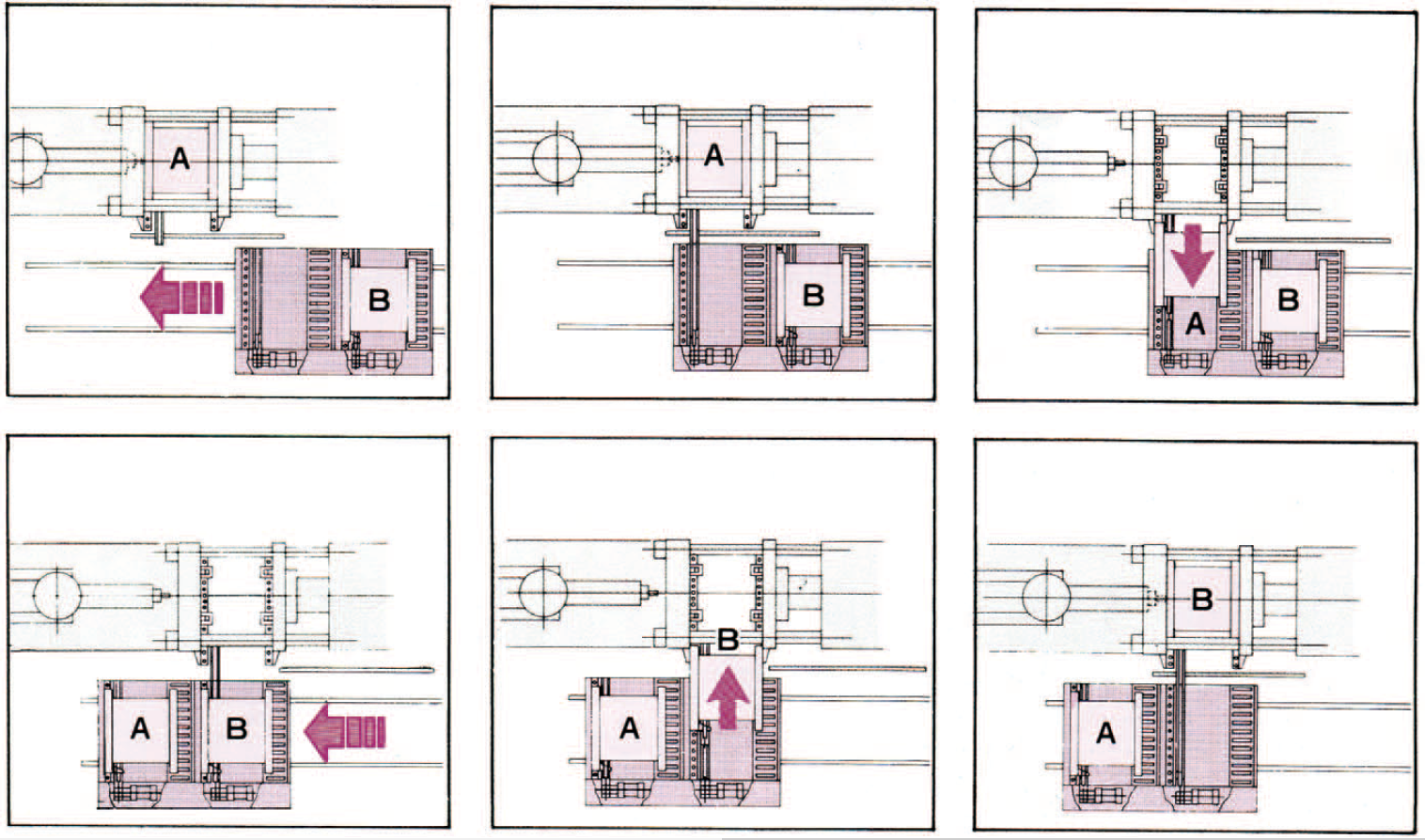

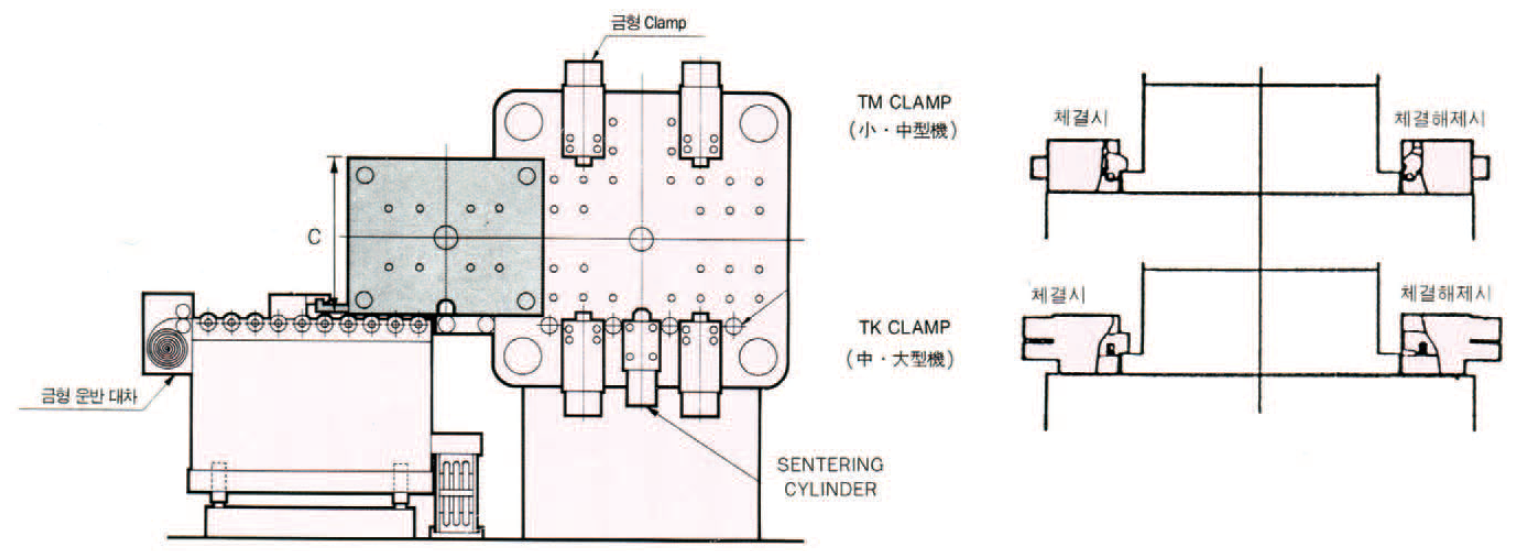

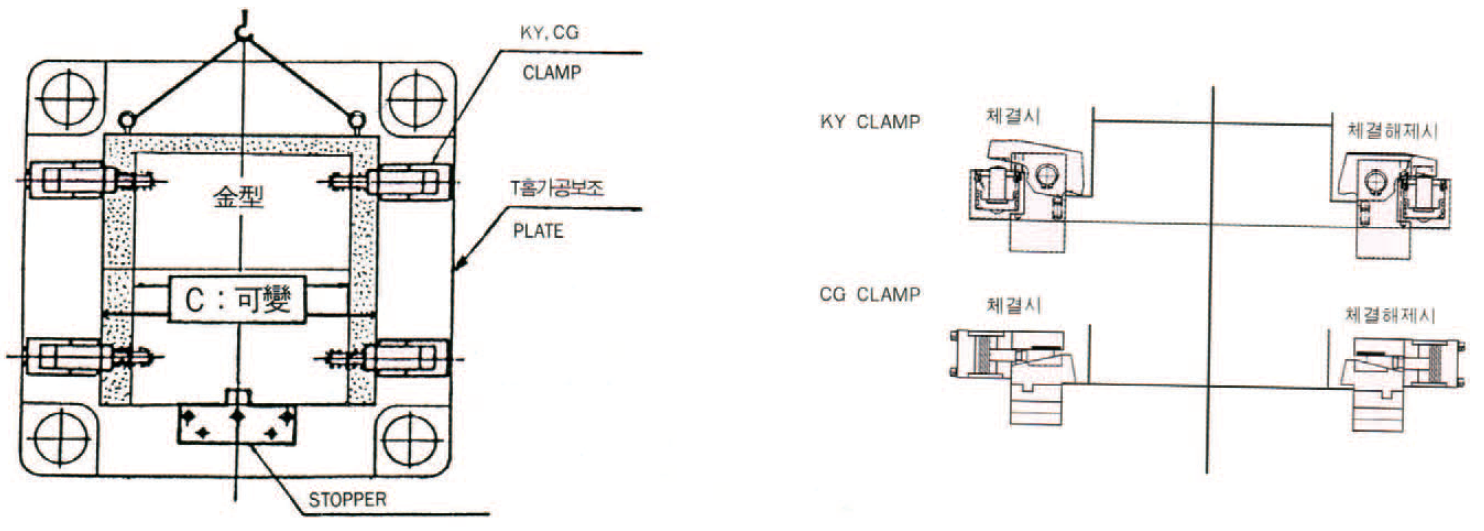

◆Left and right mold exchange method (using mold carriage)

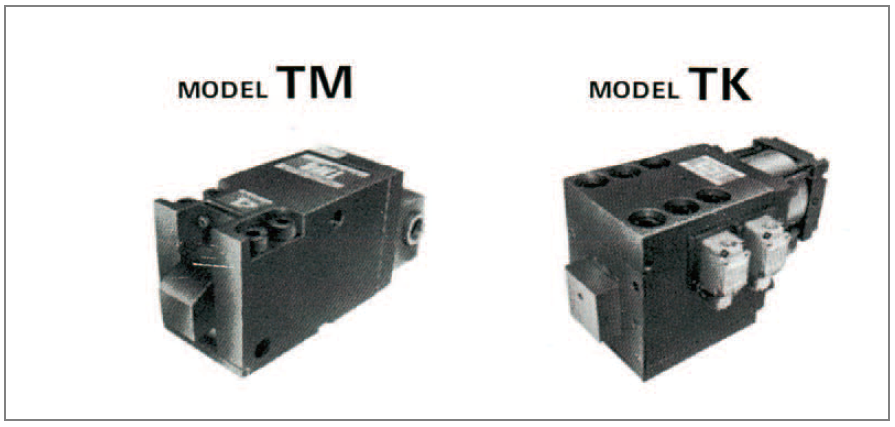

◆When mold width C is constant.

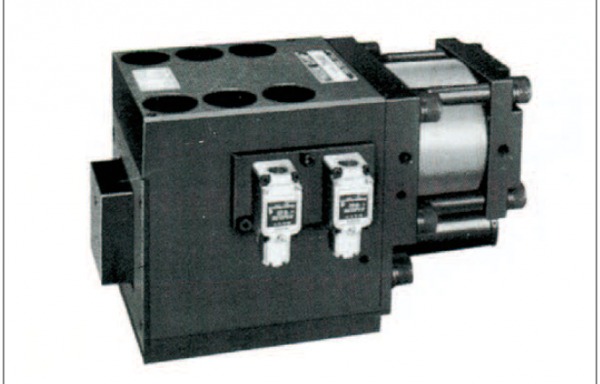

•This type is used main for the injection molding machines of

1000T or above. It has strong clamping force and safety feature

that supports the die firmly even in case of zero hydraulic

pressure.

•Only while clamping, the clamp jaw comes out. When releasing,

the jaw retreats into the clamp body

•This type is adequate for the Medium-large size injection molding

machines.

◆When the mold width C is variable.

•With the double-acting Cylinder structure, the hydraulic pressure

works while clamping, and unclamping.

•Since the Cylinder part and the lever part are separated, a

uniform force is applied on the T-slot shape & measure

•In case of broken hydraulic Line, the secure Interlock automatically

stop to operate Injection molding machine.

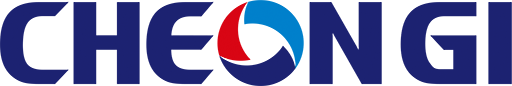

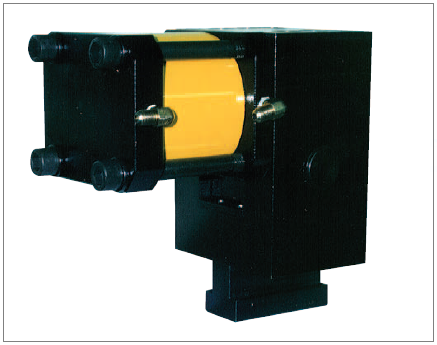

◆INJECTION & DIE- CASTING MACHINE

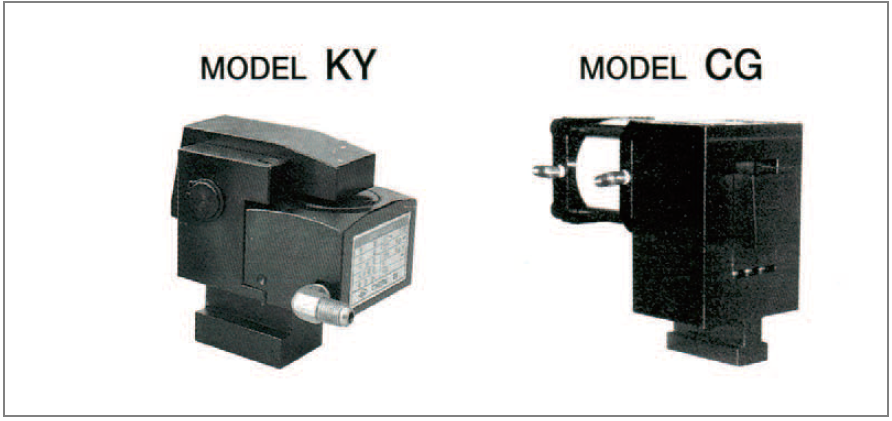

◆Selecting clamp

•If the capacity of an Injection molding machine is 550 ton, the opening force of the injection molding machine is 40 ton and eight of 10ton TM-type

or 10ton KY-type clamp are required.

•How to select the clamping force for the opening force of the Injection molding machine

Opening force / the number of clamp = ( )ton

MOLD CHANGE SYSTEM – Injection machine