HI-LOCK UNIT

Description

◆Overview

•HU type(hi-lock unit)is a hydraulic device composed of the pump(air drive hydraulic pump) and the air-pilot operating

Direction-valve(non-leak type).

•Since can be attached to the manifold, this unit can be used for different purposes due to various applcations even though it

is a compact type.

•For operating type, the Electrical operating system[HU-S] that can be operated remotely and the Mannual operating system[HU-M]are available.

•The standard type has the pressure gauge and the air filter. With air supply, high hydraulic pressure can be easily obtained

in any condition. So this unit can be applied to the automated machines, such as the clamp party, the locking system, etc

◆Appellation

HU – ① – ②S – ③ – ④ – A

| ① No. of circuits | |

| Non | 1circuit |

| 2 | 2circuit |

| 3 | 3circuit |

| 4 | 4circuit |

| ② No. of acting valve | |

| 1 | 1EA |

| 2 | 2EA |

| 3 | 3EA |

| 4 | 4EA |

| ③ Option | |

| Non | |

| R | Relief valve |

| L | Inter Lock circuit |

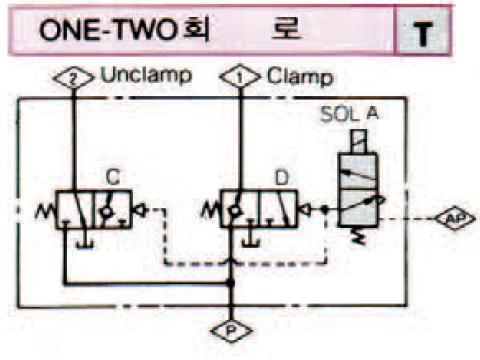

| T | One Two circuit |

| ④ PUMP type | |

| 70-8 | 70-8 |

| 70-10 | 70-10 |

| 70-12 | 70-12 |

| 100-12 | 100-12 |

| 100-15 | 100-15 |

◆BOX TYPE

| Standard | SIZE |

| 1S | 506×260×500(H) |

| 2S | 506×260×500(H) |

| 3S | 628×260×500(H) |

| 4S | 680×260×500(H) |

◆Common items

| Maximum applicable pressure | 400kgf/㎠ |

| Maximum air supply pressure | 9.5kgf/㎠ |

| Reducing valve pressure setting range | 2~6kgf/㎠ |

| Applicable temperature range | 35~60℃ |

| Solenoid valve | AC100V/100V AC200V/220V 50/60Hz |

| Applicable oil | General hydraulic oil |

※ These specification can be changed for improvement or other reason without notice.

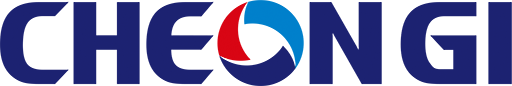

◆Shapes & Measure

| Type

Specifications |

L | ℓ | ℓ1 | H | h | W | b | t | TANK

CAP、(ℓ) |

Quantity of oil(ℓ) | Weight(kg) |

| HU-1-70- | 393 | 353 | 123 |

380 |

315 |

150 |

80 |

4.5 |

5.7 | 1.4 | 25.5 |

| HU-2-70- | 455 | 415 | 185 | 7.0 | 1.7 | 34.2 | |||||

| HU-3-70- | 517 | 477 | 247 | 8.2 | 2.0 | 42.9 | |||||

| HU-4-70- | 579 | 539 | 123 | 9.4 | 2.3 | 51.6 | |||||

| HU-1-100- | 423 | 383 | 309 |

405 |

340 |

175 |

105 |

6 |

8.6 | 2.7 | 39.0 |

| HU-2-100- | 485 | 445 | 185 | 10.2 | 3.2 | 48.4 | |||||

| HU-3-100- | 547 | 507 | 247 | 11.9 | 3.7 | 57.8 | |||||

| HU-4-100- | 609 | 569 | 309 | 13.5 | 4.3 | 67.2 |

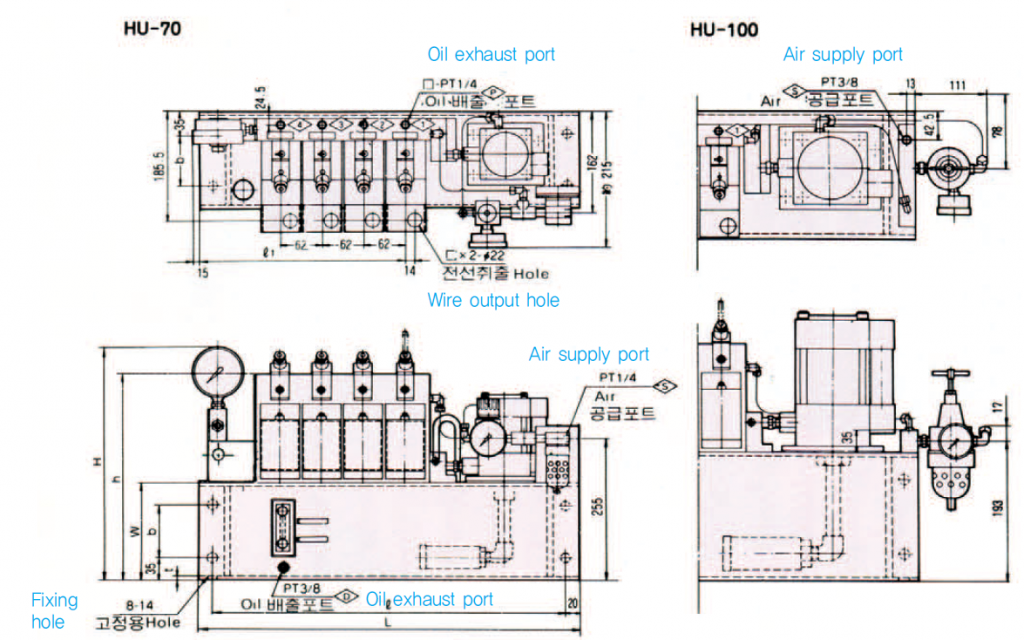

PUMP Flow rate Characteristics.

Conditions : Oil temperature 20℃

PA : supplied air pressure

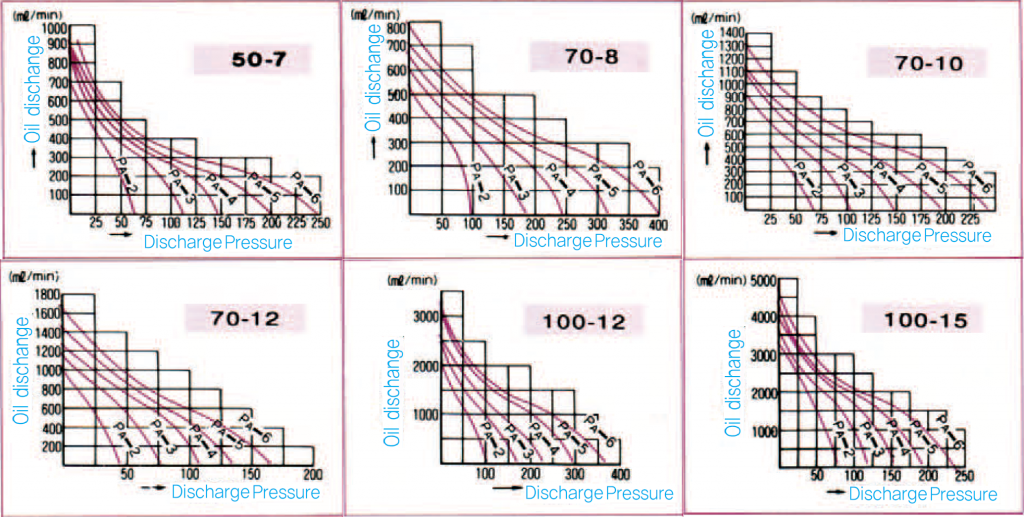

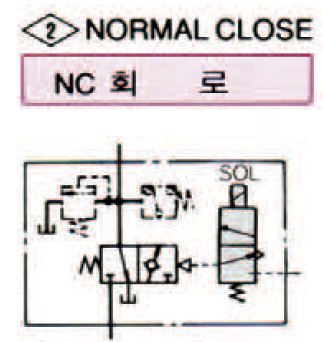

When the solenoid is

turned on,the pressure is

transmitted. This is the

most suitable for the die

lifter

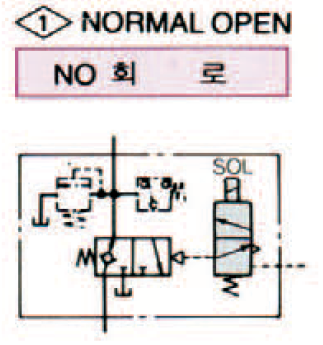

When the solenoid is turned off,

the pressure is transmitted. So

this is the most suitable for the

clamp circuit.(The pressure is

maintained in case of power

failure or breaking-off air supply).

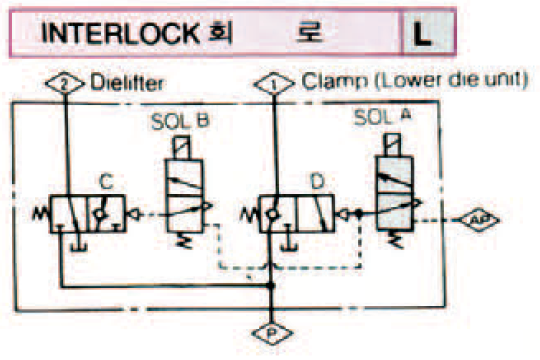

When SOL(A)is turned off, the air-pilot operating direction control valve C

does not operate regardless of SOL(B)-on or OFF. This is the most suitable

for being used between the die lifter and the clamp.

By SOL(A),C and D are operated.

Pressure increase & pressure gauge range

of the pump

| Type | Pressure increase (time) | Pressure gauge range |

| 50-7 | 40 | 350 |

| 70-8 | 65 | 500 |

| 70-10 | 40 | 350 |

| 70-12 | 28 | 250 |

| 100-12 | 62.5 | 500 |

| 100-15 | 40 | 350 |